NXX-52D

- introduce

◆High precision, high rigidity, heavy load sleeve simple spindle.

It adopts integral sleeve spindle, first and second imported precision spindle bearings, and spindle servo motor drive to achieve high precision, high rigidity and speed stability.

◆The bed is rigid and easy to handle and remove.

The bed is inclined at 30° or 45°. It is made of high-quality cast iron resin sand, compact and ribbed structure, good rigidity and strong shock resistance.

◆High rigidity, high precision, high speed linear slide, precision ball screw.

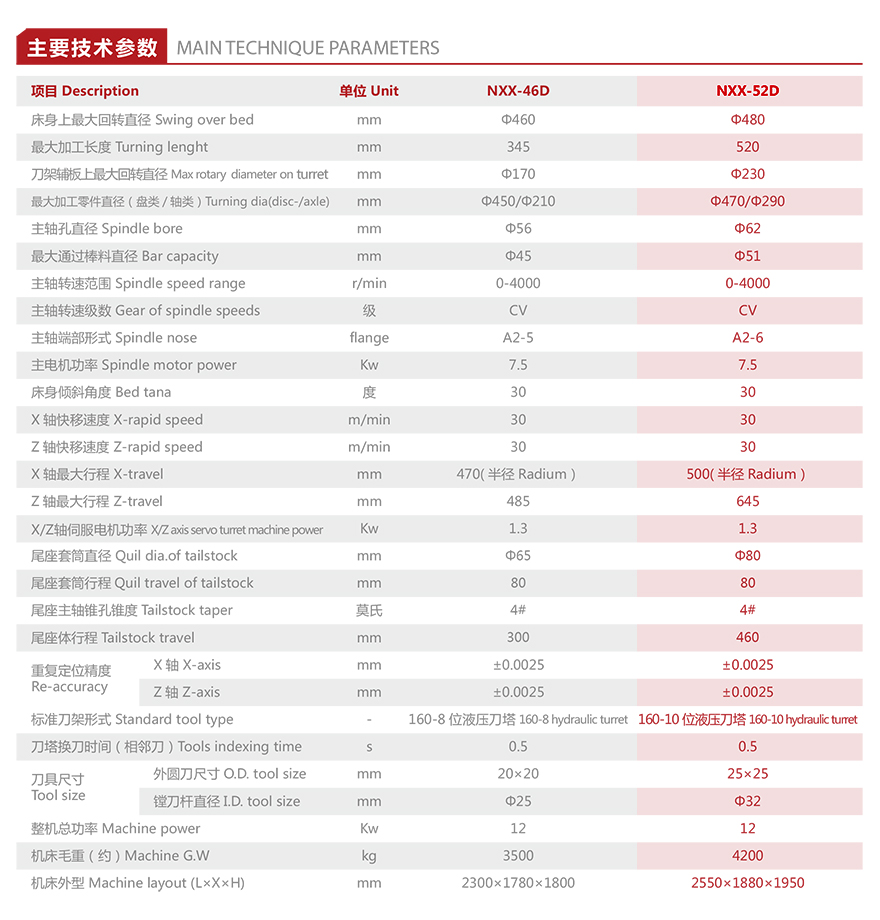

The X/Z axis is directly connected by a servo motor and a precision pre-stretched ball screw through a flexible coupling, and adopts a high-rigidity, high-precision linear slide rail. It is equipped with a computer automatic lubrication system to force lubrication of the linear guide and the ball screw. The positioning accuracy is high, the thermal deformation is small, and the moving speed can reach 30M/min.

◆The hydraulic station adopts Taiwan variable pump, hydraulic motor, solenoid valve and air-cooling device, which has low noise and low oil temperature.

◆Using Taiwan's eight-station hydraulic or servo rotary turret, the tool change is fast, the tool is changed nearby, the tool change time is 0.3-0.5 seconds and it is suitable for heavy-duty cutting.

◆The styling is fully enclosed and protected, the waterproof performance is good, the movable door is easy to open, and it is equipped with safety interlocking device.

CNC system: Taiwan Syntec Spindle parts: Domestic or Taiwan Posa Spindle servo motor/Driver: Beijing CTB X/Z axis servo motor/Driver: Taiwan Syntec or Yaskawa, Japan | X/Z axis ball screw: Taiwan PMI or Hiwin X/Z axis linear guide: Taiwan PMI or Hiwin Turret: Taiwan hydraulic or servo turret Bed base: Cast iron base, Yunnan Taizheng machine Electrical components: Schneider, France |

The address of this article:http://www.777y.com.cn/en/product/605.html

Key word:復(fù)合數(shù)控車床,復(fù)合數(shù)控車床廠,復(fù)合數(shù)控車床廠家

next:None

Recently browse:

Related news:

- Small CNC lathe manufacturers talk about common sense in lathe power supply

- What are the requirements for the use of turning and milling composite CNC lathes?

- Turning and milling composite CNC lathe manufacturers talk about the division of CNC machining process

- CNC lathe custom manufacturers to describe the positioning accuracy of small CNC lathe linear motion

- Turning and milling composite CNC lathe manufacturers talk about the main components of CNC lathes

- Turning and milling composite CNC lathe manufacturers talk about the technology of turning and milling combined machining center

- Small CNC lathe manufacturers talk about the future development of turning and milling composite CNC lathe

- CNC lathe custom manufacturers talk about the daily maintenance of lathe oil mist system

- How to improve the processing efficiency of small CNC lathes for CNC lathe custom manufacturers

- Small CNC lathe manufacturers talk about the relationship between precision and resolution of CNC machine tool encoder